All Product

-

Read More

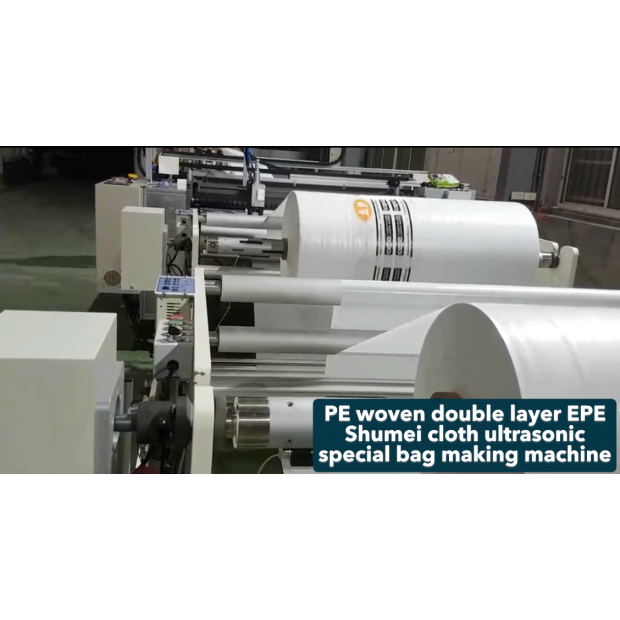

PP/PE woven laminated double layer EPE Shumei cloth ultrasonic bag making machine

PP/PE woven laminated double layer EPE Shumei cloth ultrasonic bag making machinePP/PE woven laminated double layer EPE Shumei cloth ultrasonic bag making machine

Product Description:

1. The traditional hot pressing and hot cutting processing methods have disadvantages such as preheating, energy consumption, unstable temperature, easy deformation of processed objects and poor hand feel.

2. The 20K frequency ultrasonic system currently on the market is still unable to overcome the problem of PP/PE woven bags being laminated with EPE Shumei cloth.

3.PP/PE woven bags have excellent tensile strength and durability. After being processed and bonded with EPE Shumei cloth, the woven bags have the effect of cushioning, anti-wear and anti-collision protection. Currently, the products are used in packaging materials such as automotive parts, industrial electrical products, 3C product equipment, glass panels, plastic accessories, solar panels, etc.

4. In order to solve these problems, our company has been continuously researching and developing a series of high-power and high-frequency new ultrasonic equipment and system modules, which can be installed in automated mechanical equipment in different fields and with different processing requirements to meet customized needs. -

Read More

PE-PP-PET various film packaging material sealing and cutting machines

PE-PP-PET various film packaging material sealing and cutting machinesPE-PP-PET various film packaging material sealing and cutting machines

Product Description:

1. The traditional hot pressing/hot cutting processing method has the disadvantages of preheating, energy consumption, unstable temperature, easy deformation of processed objects and poor hand feel. The use of ultrasonic heating system can greatly improve these conditions.

2. However, for special materials, traditional ultrasonic systems cannot overcome them. In order to solve these problems, our company continues to research and develop a series of new high-frequency and high-power ultrasonic system modules.

3. It can be installed in automated mechanical equipment in different fields and with different processing requirements, and can meet 100% customization requirements. -

Read More

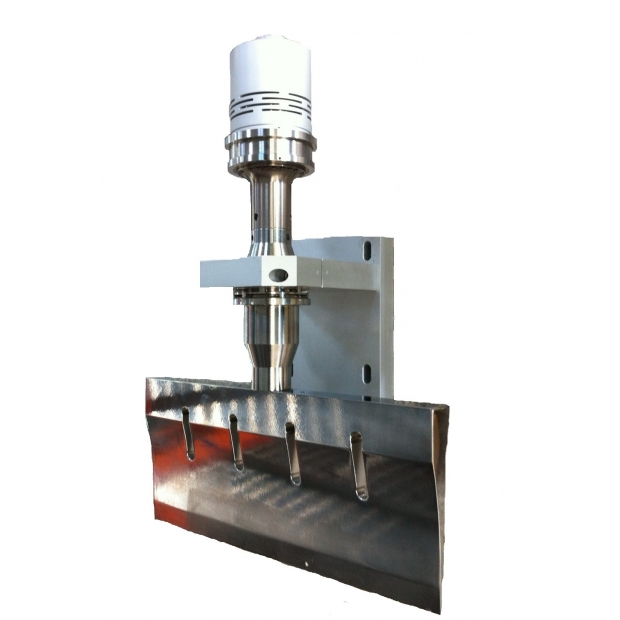

High power and high frequency PP/PE clip bag system

High power and high frequency PP/PE clip bag systemHigh power and high frequency PP/PE clip bag system

Product Description:

1. The traditional hot pressing/hot cutting processing method has the disadvantages of preheating, energy consumption, unstable temperature, easy deformation of processed objects and poor hand feel.

2. However, for special materials, traditional ultrasonic systems cannot overcome them. In order to solve these problems, our company continues to research and develop a series of new high-power and high-frequency ultrasonic system modules.

3. It can be installed in automated machinery and equipment with different fields and different processing requirements to meet highly customized requirements.

4. In order to solve these problems, our company continues to research and develop a series of new high-power and high-frequency ultrasonic equipment and system modules, which can be installed in automated machinery and equipment with different fields and different processing requirements to meet customized requirements. -

Read More

Ultrasonic high power high frequency wide width cutting machine/fabric splicing machine

Ultrasonic high power high frequency wide width cutting machine/fabric splicing machineUltrasonic high power high frequency wide width cutting machine/fabric splicing machine

Product Description:

1. The traditional hot pressing/hot cutting processing method has the disadvantages of requiring preheating, consuming energy, unstable temperature, easy deformation of the processed objects and poor hand feel.

2. For special materials, traditional ultrasonic systems cannot overcome them. To solve these problems, our company continues to research and develop a series of new high-power and high-frequency ultrasonic system modules.

3. It can be installed in automated machinery and equipment in different fields and with different processing requirements to meet highly customized requirements. -

Read More

Food grade titanium alloy cutter ultrasonic cutting machine system

Food grade titanium alloy cutter ultrasonic cutting machine systemFood grade titanium alloy cutter ultrasonic cutting machine system

Product Description:

1. This food slicer is designed for foods such as heavy cheesecake, crepe, puff, sandwich, etc.

2. Use food-grade titanium alloy knives, suitable for food cutting.

3. High power and strong amplitude design, excellent cutting effect, non-stick knives are easy to clean.

4. The thickness and length of the knives can be customized according to needs.

5. The fully automatic food cutting machine can be designed according to cutting requirements. -

Read More

Radial Ultrasonic Slit Machine Series (Horizontal Arm/Vertical Arm)

Radial Ultrasonic Slit Machine Series (Horizontal Arm/Vertical Arm)Radial Ultrasonic Slit Machine Series (Horizontal Arm/Vertical Arm)

Product Description:

1. This machine is specially developed for sewing special parts such as cuffs, trouser legs, hats or sleeves, trouser legs, etc.

2. Different from the previous longitudinal vibration fixed welding head design, a disc rotating welding head is used to make the ultrasonic vibration evenly act on the circumference of the welding head and rotate synchronously with the flower wheel.

3. This design can effectively solve the problem of traditional longitudinal ultrasonic sewing machines for sewing elastic materials, which is easy to produce squeeze, wrinkles, and ruffles. It is easy to operate whether it is straight or curved. -

Read More

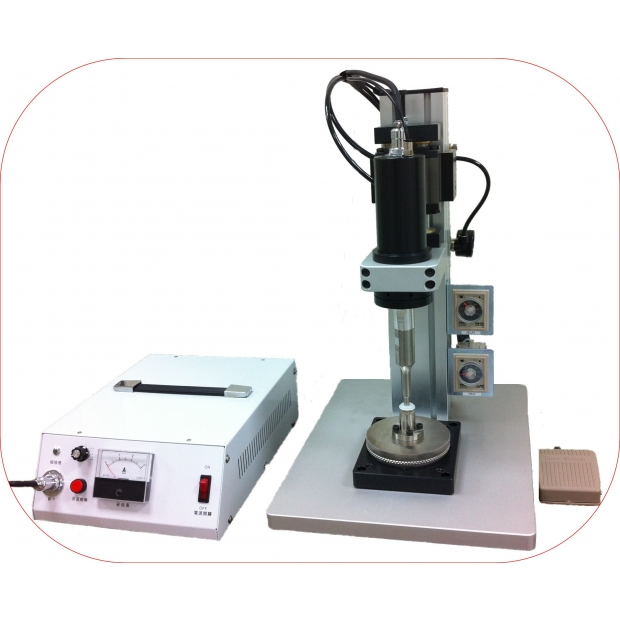

Radial ultrasonic suturing machine (desktop type)

Radial ultrasonic suturing machine (desktop type)Radial ultrasonic suturing machine (desktop type)

Product Description:

1. Different from the previous longitudinal vibration fixed welding head design, a disc rotating welding head is used to make the ultrasonic vibration act evenly on the circumference of the welding head and rotate synchronously with the flower wheel.

2. This design effectively overcomes the performance that traditional longitudinal ultrasonic slitting machines cannot achieve, especially for the slitting of elastic materials. Whether it is straight or curved sewing, it can be easily operated, and no longer produces problems such as extrusion, wrinkles, ruffles and other defective products. -

Read More

8 inch lace machine

8 inch lace machine8 inch lace machine

Product Description:

1. For edge banding, trimming or sealing and cutting of chemical synthetic fiber fabrics and thermoplastic plastic films, this machine can replace the traditional sewing machine, which is easy to cause pinholes and the trouble of assembling needles and threads, and can achieve water and air tightness.

2. It vibrates 20,000 times per second, generates high heat energy instantly, does not smoke, has no odor, does not need preheating, can be processed after turning on, has low energy consumption, high efficiency, and is easy to operate. -

Read More

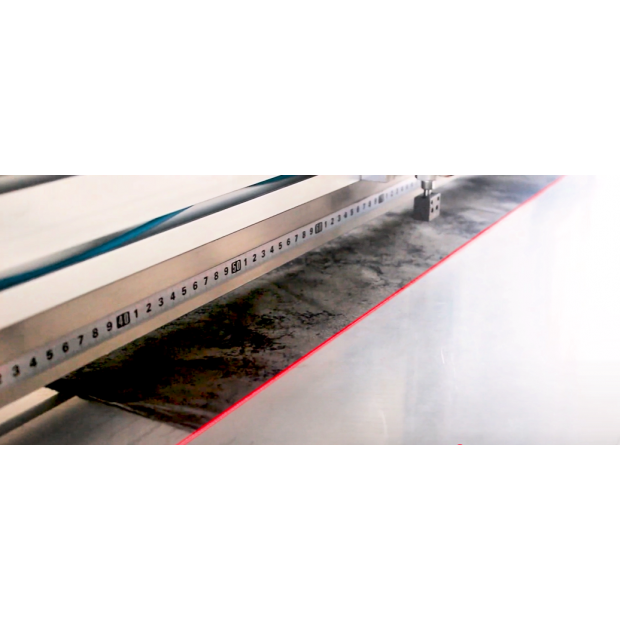

Ultrasonic wide width fabric slitting machine/cross-cutting machine

Ultrasonic wide width fabric slitting machine/cross-cutting machineUltrasonic wide width fabric slitting machine/cross-cutting machine

Product Description:

1.The traditional hot pressing/hot cutting processing method has the disadvantages of preheating, energy consumption, unstable temperature, easy deformation of processed objects and poor hand feel.

2.The use of ultrasonic heating system can greatly improve these conditions; but for special materials, the traditional ultrasonic system cannot overcome them. In order to solve these problems, our company continues to research and develop a series of high-frequency and high-power new ultrasonic system modules.

3.It can be installed in automated mechanical equipment in different fields and with different processing requirements, and can meet 100% customization requirements. -

Read More

Ultrasonic plastic carbon fiber sheet/hook and loop fastener/commercial woven label slitting machine

Ultrasonic plastic carbon fiber sheet/hook and loop fastener/commercial woven label slitting machineUltrasonic plastic carbon fiber sheet/hook and loop fastener/commercial woven label slitting machine

Product Description:

1. According to different material characteristics and processing requirements, the special slitting machine can be customized.

2. The knife wheel can be designed to slit multiple strips at one time, or the knife seat can adjust the knife distance.

3. Cutting and overlapping parts can be added to ensure uninterrupted production and save material consumption.

4. Install high-efficiency dust collection equipment to prevent dust explosions and reduce air pollution in the factory. -

Read More

Ultrasonic Ear-loop Non-woven Coffee Bag Automatic Filling Machine

Ultrasonic Ear-loop Non-woven Coffee Bag Automatic Filling MachineUltrasonic Ear-loop Non-woven Coffee Bag Automatic Filling Machine

Product Description:

1. The traditional hot pressing and hot cutting processing method has the disadvantages of preheating, energy consumption, unstable temperature, easy deformation of processed objects and poor hand feel.

2. The use of ultrasonic heating system can greatly improve the situation of traditional hot pressing and hot cutting, but the traditional ultrasonic system cannot overcome the ever-changing special materials.

3. In order to solve these problems, our company continues to research and develop a series of high-frequency and high-power new ultrasonic system modules, which can be installed in automated mechanical equipment in different fields and with different processing requirements to achieve 100% customization requirements. -

Read More

Ultrasonic high frequency high power pneumatic simple melting and cutting machine

Ultrasonic high frequency high power pneumatic simple melting and cutting machineUltrasonic high frequency high power pneumatic simple melting and cutting machine

Product Description:

1. The traditional hot pressing and hot cutting processing method has the disadvantages of preheating, energy consumption, unstable temperature, easy deformation of processed objects and poor hand feel.

2. The use of ultrasonic heating system can greatly improve the situation of traditional hot pressing and hot cutting, but the traditional ultrasonic system cannot overcome the ever-changing special materials.

3. In order to solve these problems, our company continues to research and develop a series of high-frequency and high-power new ultrasonic system modules, which can be installed in automated mechanical equipment in different fields and with different processing requirements to achieve 100% customization requirements.